When it comes to heavy-duty earthmoving tasks, excavators play an indispensable role. These powerful machines are equipped with a wide array of attachments that enable them to handle diverse projects efficiently. Among these attachments, the excavator shell bucket stands out as a remarkable tool designed for excavation and material handling tasks. In this article, we will delve into the world of hydraulic clamshell bucket for excavator, exploring their design, functionality, and the groundbreaking advancements that have made them an indispensable asset in the construction and mining industries.

-

The Anatomy of an Excavator Shell Bucket:

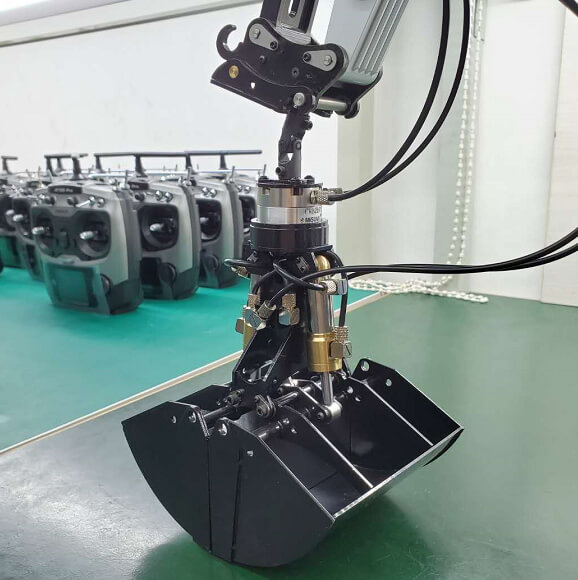

Hydraulic clamshell bucket for excavator is a large, robust attachment designed to fit onto the arm or boom of an excavator. It consists of a hinged frame, typically made of durable steel, with two shell-shaped jaws that close to form a bucket. The shells can be either fixed or hinged, depending on the specific application.

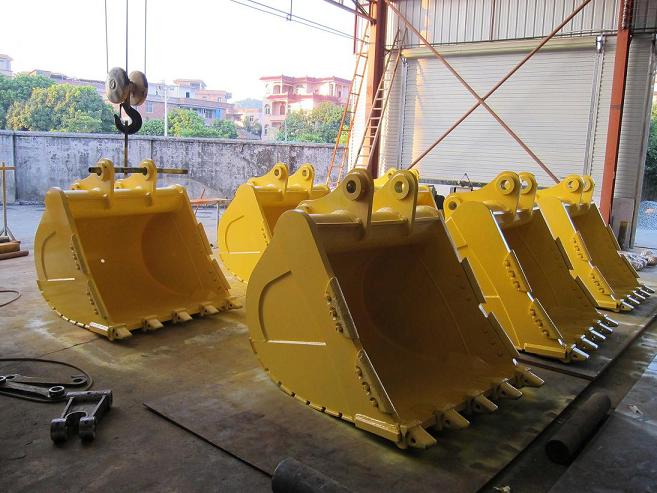

The jaws of the bucket are lined with hardened steel teeth that facilitate gripping and digging into various types of soil, rocks, or other materials. The spacing and arrangement of these teeth vary depending on the purpose of the bucket. Some buckets have wider spacing for scooping loose materials, while others feature closely spaced teeth for excavating dense soils.

To enhance the bucket’s strength and durability, manufacturers employ advanced welding techniques and use high-strength steel alloys. Additionally, wear-resistant materials like Hardox plates are often added to the critical areas of the bucket, such as the cutting edge and the sides, to increase their lifespan.

-

Versatility and Functionality:

Excavator shell buckets are highly versatile attachments due to their ability to handle a wide range of tasks. They excel in applications such as digging trenches, excavating foundations, loading and unloading bulk materials, and sorting debris on construction sites.

One notable feature of shell buckets is their ability to perform precise digging operations. The jaws can be independently controlled, allowing for efficient excavation in tight spaces and around obstacles. This versatility significantly reduces the need for manual labor and makes excavator shell buckets indispensable tools in urban construction projects.

Furthermore, some hydraulic clamshell bucket for excavator come equipped with additional features that enhance their functionality. For instance, some models have replaceable cutting edges, allowing operators to maintain peak performance by replacing worn-out edges rather than the entire bucket. Others may have hydraulic cylinders that provide added gripping force, making it easier to handle heavy loads.

-

Advancements in Excavator Shell Bucket Technology:

The field of hydraulic clamshell bucket for excavator has witnessed significant advancements in recent years. One notable development is the integration of telematics and sensor technologies. Intelligent systems can monitor the bucket’s performance in real-time, providing valuable data on factors like productivity, material density, and wear and tear. This data can be utilized to optimize excavation processes, minimize downtime, and extend the bucket’s lifespan.

Another groundbreaking innovation is the introduction of reversible shell buckets. Unlike traditional buckets that can only dig in one direction, reversible buckets can dig in both forward and backward motions. This feature enhances productivity by eliminating the need to reposition the excavator frequently. Reversible buckets are particularly advantageous in tasks such as cleaning ditches or creating trenches where efficiency is paramount.

Additionally, manufacturers have focused on improving the ease of maintenance for excavator shell buckets. Quick coupler systems enable operators to swiftly change attachments, reducing downtime between tasks. Moreover, advancements in wear-resistant materials have resulted in buckets that can withstand intense wear and abrasion, significantly reducing the need for frequent replacements.

Conclusion:

Hydraulic clamshell bucket for excavator have revolutionized the field of earthmoving and material handling. Withtheir robust design, versatility, and continuous technological advancements, these attachments have become invaluable assets in the construction and mining industries.

Excavator shell buckets have proven their worth in a wide range of applications, from digging and excavation to material handling and sorting. Their precise control and ability to maneuver in tight spaces make them ideal for urban construction projects where space is limited. Additionally, the integration of telematics and sensor technologies has enabled operators to optimize their performance and extend their lifespan, leading to improved efficiency and reduced downtime.

One of the most notable advancements in hydraulic clamshell bucket for excavator technology is the introduction of reversible buckets. This innovation has significantly increased productivity by eliminating the need for frequent repositioning of the excavator. With reversible buckets, operators can dig in both forward and backward motions, making tasks such as ditch cleaning and trenching more efficient.

Maintenance has also been simplified with the introduction of quick coupler systems. These systems allow for swift attachment changes, reducing downtime and increasing operational efficiency. Moreover, the use of wear-resistant materials, such as Hardox plates, has greatly improved the durability and lifespan of excavator shell buckets, reducing the frequency of replacements and associated costs.

Looking ahead, the future of excavator shell buckets appears promising. As technology continues to advance, we can expect further innovations in terms of efficiency, precision, and durability. Excavator shell buckets will continue to play a vital role in transforming the way we approach earthmoving projects, enabling faster and more cost-effective construction processes while minimizing environmental impact.

In conclusion, hydraulic clamshell bucket for excavator have revolutionized the field of earthmoving and material handling. These robust attachments, with their versatility and advanced features, have become indispensable tools in the construction and mining industries. With ongoing technological advancements, the future of excavator shell buckets looks bright, promising increased efficiency, precision, and durability for a wide range of earthmoving tasks.

Leave A Comment