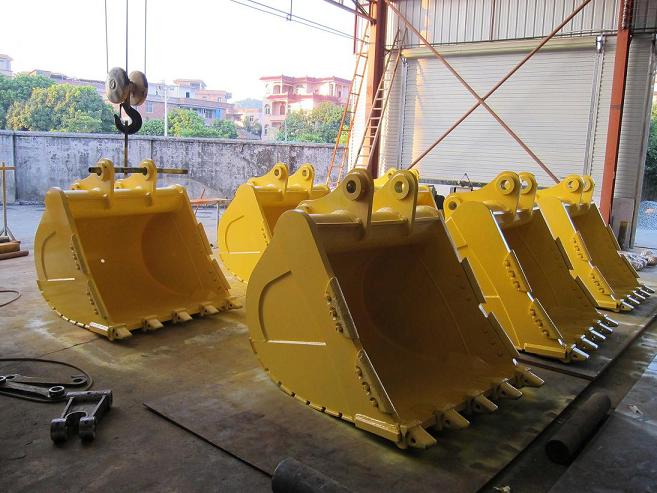

When selecting an excavator bucket, knowing how to assess its quality can be the difference between an efficient operation and a costly mistake. Excavator buckets come in various types and are designed to meet different challenges in excavation projects. Here, we’ll explore how to distinguish high-quality excavator buckets from lesser ones by focusing on several key aspects.

Excavator Bucket Material Quality: The Foundation of Durability

The first aspect to examine is the material from which the bucket is made. High-quality excavator buckets are typically constructed using wear-resistant steel such as HARDOX. This type of steel ensures the bucket can withstand the harsh conditions of digging, scooping, and dumping without deteriorating quickly.

How to Distinguish:

Check the specifications or ask the manufacturer about the type of steel used.

Look for certifications or material grades marked on the bucket.

Higher-grade steels are often a hallmark of better quality.

Excavator Bucket Build and Construction: Assessing Craftsmanship

The build quality of an excavator bucket affects its durability and efficiency. Good craftsmanship is characterized by robust construction where all parts are securely assembled.

How to Distinguish:

Examine the welding areas; consistent, smooth welds without gaps or inconsistencies suggest quality.

Check for reinforcements at stress points such as side cutters, wear strips, and around the bucket’s throat.

Look at the thickness of the bucket’s walls and the base. Thicker plates usually indicate a bucket designed for heavier use.

Excavator Bucket Design and Shape: Suitability for Purpose

Different tasks require different bucket designs. The design and shape of the bucket should match the specific needs of the job, whether it’s heavy-duty rock breaking or fine grading.

How to Distinguish:

Analyze the bucket’s design relative to its intended use. For instance, a rock bucket should have a narrower shape with ripper teeth.

Ensure the bucket shape allows for maximum efficiency in material penetration and retention during operation.

Excavator Bucket Compatibility and Fit: Ensuring Efficient Operation

A bucket must fit the excavator perfectly to transmit the machine’s power efficiently. An ill-fitting bucket not only reduces efficiency but also increases wear on both the bucket and the excavator.

How to Distinguish:

Verify bucket compatibility with your excavator model, focusing on the pin size, the distance between mounts, and the weight class.

Consult with manufacturers or specialists to ensure the bucket is appropriate for your excavator’s hydraulic capabilities.

Brand Reputation and Reviews: Learning from Others

Established brands are often synonymous with quality due to consistent manufacturing standards and customer satisfaction.

How to Distinguish:

Research online for customer reviews and testimonials regarding the bucket’s performance.

Consider feedback from forums and industry contacts who have used similar products.

Wear and Tear Indicators: Evaluating Used Excavator Bucket

If you’re considering a used excavator bucket, it’s crucial to inspect it for any signs of excessive wear and tear, which can significantly impact its longevity and performance.

How to Distinguish:

Look for any visible cracks, dents, or significant rusting on the bucket.

Check the condition of the cutting edge and teeth for wear patterns.

Ensure that there is no bending or distortion in the bucket’s frame, as this can indicate past overloading.

Innovative Features: Added Advantages

Some buckets offer innovative features that can improve their functionality and adaptability to various conditions. These features might include adjustable settings, replaceable teeth, or built-in sensors for performance monitoring.

How to Distinguish:

Identify any additional features that enhance the bucket’s utility and assess whether these innovations are of genuine benefit to your specific needs.

Evaluate the integration of these features; well-integrated enhancements suggest a well-designed bucket.

Conclusion

Selecting the right excavator bucket is crucial for efficient operations in construction, mining, or any other field involving excavation. By examining the material quality, build and construction, design and shape, compatibility and fit, brand reputation, condition of used buckets, and any innovative features, you can make an informed decision that ensures both productivity and cost-efficiency. Remember, a high-quality excavator bucket is an investment in your project’s success and safety.

Feel free to delve into each of these aspects in your own context, and use these tips to guide your evaluations when choosing the best excavator bucket for your needs.

Leave A Comment