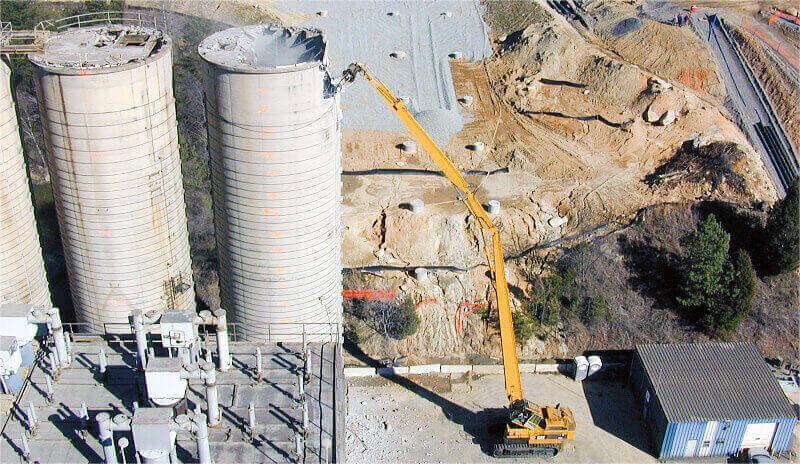

Excavator demolition arms are impressive pieces of machinery that are widely used in the construction industry. They are specifically designed to demolish buildings, bridges, and other structures that need to be taken down. In this article, we will discuss the process of how the excavator demolition arm is made.

Design

The first step in making an excavator demolition arm is to design the arm itself. Engineers and designers work together to create a blueprint that outlines the exact specifications of the arm. They take into account factors such as the weight and size of the arm, the materials to be used, and the maximum weight it will need to carry.

Once the design is complete, the manufacturing process can begin. The first step is to cut and shape the metal that will be used to construct the arm. Typically, this is done using a large cutting machine that can handle the thickness of the metal. The metal is then shaped using a press machine or a bending machine to give it the required shape.

After the metal is cut and shaped, it is time to weld the pieces together. This is done using an arc welding machine, which uses an electric arc to melt the metal and create a strong bond between the pieces. The welding process is crucial, as the strength of the arm will depend on the quality of the welds.

Once the arm has been welded together, it is time to add the hydraulic system. The hydraulic system is what allows the arm to move and operate. It consists of hydraulic pumps, valves, and hoses that are all connected to a control panel. The control panel allows the operator to control the arm’s movements and adjust the amount of pressure that is being applied.

Finally, the excavator demolition arm is painted and given a protective coating to prevent rust and corrosion. The paint and coating not only make the arm look more attractive, but they also extend its lifespan and ensure that it can withstand the harsh conditions it will face in the construction industry.

In conclusion, the process of making an excavator demolition arm is a complex one that involves careful planning, precise cutting and shaping, expert welding, and the installation of a sophisticated hydraulic system. The result is a powerful and efficient piece of machinery that can take down even the most challenging structures with ease.

Leave A Comment