In the world of heavy machinery, the excavator hydraulic drum cutter stands out as a remarkable piece of equipment that has revolutionized the fields of demolition and excavation. With its immense power and precision, this formidable tool has become an indispensable asset for construction projects around the globe. In this article, we delve into the inner workings and capabilities of the excavator hydraulic drum cutter, exploring its various applications, advantages, and the technology that drives its performance.

Unleashing the Power:

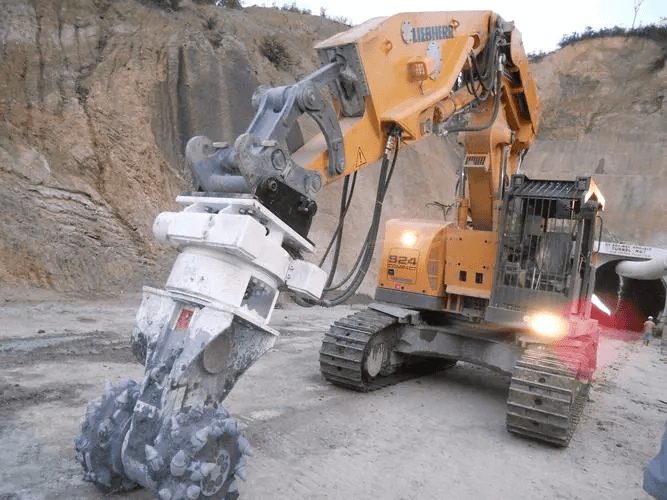

At the heart of the excavator hydraulic drum cutter lies its defining feature, the drum. This cylindrical cutting attachment is fitted with a series of replaceable teeth or picks, designed to slice through tough materials with exceptional efficiency. Powered by hydraulic systems, the drum cutter can be attached to the arm of an excavator, enabling it to perform a wide range of cutting, grinding, and excavating tasks. The hydraulic power not only drives the rotation of the drum but also allows for precise control over the cutter’s movement, ensuring maximum accuracy and safety.

Versatility in Applications:

The excavator hydraulic drum cutter finds its utility across various industries. In the field of demolition, it excels at reducing concrete structures, demolishing walls, and slicing through thick layers of reinforced steel. Its powerful cutting action can swiftly dismantle buildings, bridges, and other structures, significantly expediting the demolition process while minimizing environmental impact.

Moreover, the drum cutter’s versatility extends to excavation tasks. It can be effectively employed for trenching, tunneling, and general excavation projects. By precisely removing layers of soil and rock, the drum cutter enables a more controlled and efficient excavation process. Its ability to operate in confined spaces and uneven terrains makes it particularly suitable for urban construction projects where precision is paramount.

Advantages of the Excavator Hydraulic Drum Cutter:

The excavator hydraulic drum cutter offers several advantages over traditional cutting methods. Firstly, its powerful cutting action reduces the need for manual labor and handheld tools, thereby improving overall safety and reducing the risk of operator fatigue and injuries. Additionally, the drum cutter’s ability to rotate 360 degrees allows it to access hard-to-reach areas without requiring the excavator to constantly reposition itself. This feature significantly enhances productivity and saves valuable time on construction sites.

Furthermore, the drum cutter’s replaceable picks ensure long-lasting performance and cost-effectiveness. When the picks become worn out, they can be easily replaced, eliminating the need for frequent tool replacements or repairs. This reduces downtime and maintenance costs, contributing to increased profitability for construction companies.

Technology Behind the Performance:

The hydraulic systems that power the excavator hydraulic drum cutter play a vital role in its exceptional performance. High-pressure hydraulic fluid is channeled through the cutter’s hydraulic motor, driving the rotation of the drum. This hydraulic motor, coupled with advanced hydraulic controls, allows operators to adjust the cutting speed and pressure, providing precise control over the cutting action. The excavator’s hydraulic system also facilitates the precise positioning and movement of the drum cutter, ensuring optimal performance even in challenging conditions.

Future Innovations:

As technology continues to advance, we can expect further innovations in excavator hydraulic drum cutter design and capabilities. Manufacturers are continuously exploring ways to enhance cutting efficiency, reduce noise levels, and improve the overall sustainability of these machines. Additionally, advancements in remote control and autonomous technologies may enable operators to control drum cutters from a safe distance, further improving safety and expanding their applications.

Conclusion:

The excavator hydraulic drum cutter has undoubtedly revolutionized the fields of demolition and excavation. With its immense power, versatility, and precision, it has become an indispensable tool for construction projects worldwide. By simplifying complex tasks, enhancing safety, and improving productivity, the drum cutter has significantly transformed the way construction projects are executed.

Looking ahead, the future of excavator hydraulic drum cutters appears promising. With ongoing technological advancements, we can anticipate even more efficient and sustainable designs. Manufacturers are likely to focus on developing cutting-edge materials for the drum picks, enhancing their durability and longevity. This, in turn, will contribute to cost savings and reduce environmental waste.

Moreover, the integration of intelligent systems and automation technologies holds immense potential for the drum cutter’s evolution. Imagine a drum cutter equipped with sensors and advanced algorithms that can analyze the properties of the material being cut in real-time. This would enable the machine to adjust its cutting parameters automatically, optimizing performance and ensuring minimal waste. Additionally, the implementation of remote control and autonomous capabilities could further enhance safety and productivity, allowing operators to control multiple drum cutters simultaneously from a central location.

Another area of interest for future development lies in noise reduction. Although drum cutters are already designed to operate with minimal noise levels compared to traditional cutting methods, further advancements can be made to reduce noise pollution even further. This would be beneficial for construction projects in urban areas, where noise regulations are stringent, and noise disturbances need to be minimized.

Furthermore, as sustainability becomes an increasingly vital aspect of construction practices, manufacturers may explore alternative power sources for drum cutters. Integrating electric or hybrid power systems could significantly reduce carbon emissions and enhance the overall environmental friendliness of these machines.

In conclusion, the excavator hydraulic drum cutter has emerged as a game-changing tool in the construction industry. Its unparalleled power, versatility, and precision have redefined the way demolition and excavation tasks are carried out. With ongoing technological advancements, we can expect even more efficient, sustainable, and intelligent drum cutters in the future. These machines will continue to play a vital role in shaping the infrastructure of our world, enabling safer, faster, and more precise construction processes.

Leave A Comment