When it comes to heavy machinery in construction and mining, excavators play a vital role in shaping our modern world. Among the various attachments that enhance the efficiency and versatility of these machines, skeleton buckets stand out as a remarkable innovation. These powerful tools are designed to perform rigorous digging and sorting tasks, ensuring optimal performance and maximum productivity. In this article, we will delve into the fascinating world of excavator grid bucket, exploring their design, functionality, and the impact they have on construction and mining operations.

The Anatomy of an Excavator Grid Bucket:

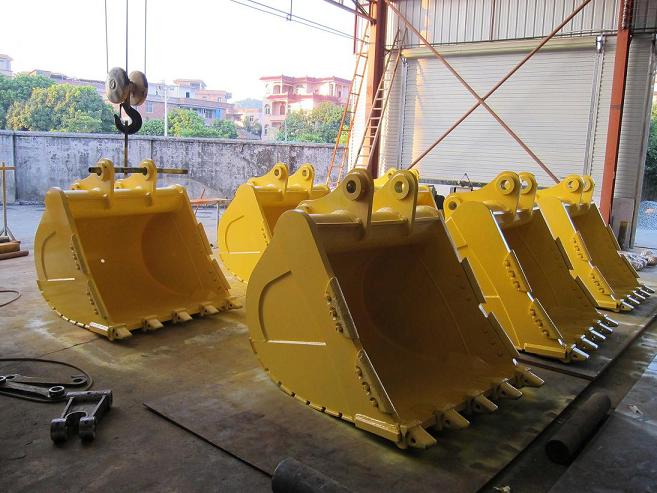

The skeleton bucket, also known as a shaker bucket, is a robust attachment specifically engineered for excavators. Its design consists of a series of sturdy, interlocking metal bars or ribs, which form a skeletal structure. These bars are strategically placed to create a lattice-like pattern that allows for efficient sorting and filtering of excavated materials.

The primary purpose of a excavator grid bucket is to separate and sift through different types of materials, such as rocks, debris, and soil, while retaining larger objects. The gaps between the bars vary in size, depending on the desired application. Some buckets have wider gaps for sifting through finer materials, while others have narrower gaps for more precise sorting.

The Power of Sorting and Sifting:

Excavator grid bucket excel in scenarios that require the separation of unwanted materials from the desired ones. In construction sites, these buckets are instrumental in tasks like excavating trenches, clearing construction debris, and sifting soil. They efficiently remove rocks, sticks, and other debris while allowing the soil to pass through, resulting in cleaner and more refined material.

In the mining industry, skeleton buckets prove invaluable during the extraction and sorting process. As excavators dig through ore deposits, the skeleton bucket allows for the separation of valuable minerals from waste rock. This process increases the efficiency of mining operations by reducing the amount of material that needs to be transported, processed, and ultimately discarded.

The Benefits of Skeleton Buckets:

Excavator grid bucket offer several key advantages that make them indispensable tools in construction and mining:

- Enhanced Efficiency: By selectively retaining larger objects and sorting through excavated material, skeleton buckets save time and effort by eliminating the need for manual sorting.

- Versatility: Skeleton buckets can be used in various applications, from landscaping and site preparation to mining and material handling. They are easily interchangeable with other excavator attachments, maximizing the equipment’s flexibility.

- Durability: Built with robust materials and reinforced ribs, skeleton buckets are designed to withstand harsh working conditions, ensuring longevity and minimal downtime.

- Cost-Effectiveness: The use of skeleton buckets optimizes material utilization, reducing the need for additional equipment or manual labor. This, in turn, lowers operational costs and increases overall project efficiency.

Conclusion:

Excavator skeleton buckets have revolutionized construction and mining operations, offering an efficient and versatile solution for sorting and sifting excavated materials. Their ability to separate valuable resources from waste materials has significantly improved the productivity and cost-effectiveness of various industries. As technological advancements continue, we can expect further innovations in the design and functionality of skeleton buckets, contributing to more sustainable and efficient construction and mining practices.

Exploring Future Developments:

The world of excavator skeleton buckets is constantly evolving, with ongoing research and development aimed at further enhancing their performance and expanding their capabilities. As technology advances, we can expect to see exciting developments in the field.

One area of focus is improving the sorting efficiency of skeleton buckets. Engineers are exploring new designs that offer even finer gap sizes, allowing for more precise separation of materials. Additionally, advancements in automation and sensor technology could enable the integration of intelligent sorting systems into skeleton buckets, further streamlining the process and reducing human error.

Another aspect being explored is the integration of additional functionalities into skeleton buckets. For example, some researchers are investigating the incorporation of magnets to enable the extraction of ferrous metals during sorting operations. This innovation would enhance the versatility of skeleton buckets, making them even more valuable in waste management and recycling applications.

Furthermore, materials used in the construction of skeleton buckets are also being examined. Engineers are exploring the utilization of advanced alloys and composite materials to improve durability and reduce the weight of the buckets without compromising strength. Lighter buckets would not only enhance fuel efficiency but also allow for the use of larger excavators, increasing the overall capacity and productivity of construction and mining operations.

Conclusion:

Excavator grid bucket have revolutionized the construction and mining industries, providing efficient sorting and sifting capabilities. As technology advances, these versatile attachments will continue to evolve, offering improved sorting efficiency, additional functionalities, and enhanced durability. With ongoing research and development, we can anticipate further advancements that will optimize construction and mining operations, improving productivity, reducing costs, and promoting sustainable practices. Excavator skeleton buckets are a testament to human ingenuity and our commitment to pushing the boundaries of innovation in pursuit of a better and more efficient future.

Leave A Comment