Excavators, the mighty machines capable of moving tons of earth with ease, owe much of their incredible efficiency to one crucial component: the excavator bucket. These robust workhorses have revolutionized the construction and mining industries, enabling efficient digging, loading, and material handling tasks. In this popular science copy, we will delve into the fascinating world of excavator bucket, exploring their production process, design features, and various applications, all contributing to their unrivaled performance.

-

The Birth of an Excavator Bucket:

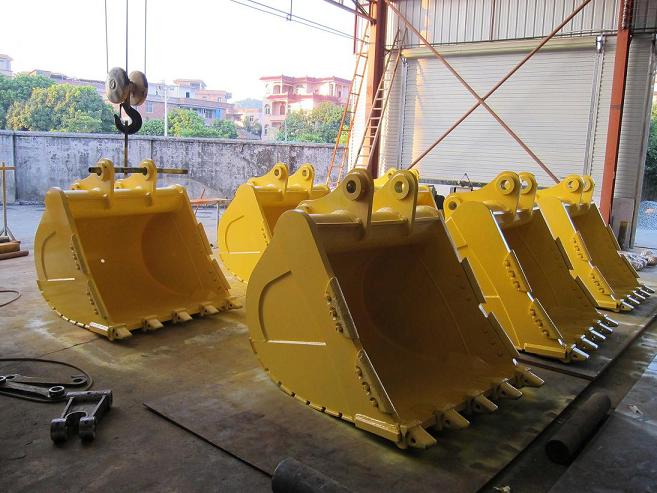

The production of an excavator bucket is a meticulous process that involves skilled craftsmanship and advanced manufacturing techniques. High-quality steel plates are meticulously cut and shaped, then welded together to form the sturdy structure of the bucket. Reinforcements and wear-resistant materials are strategically added to ensure durability and extended lifespan.

-

Design for Performance:

Excavator bucket come in a diverse range of shapes and sizes, each tailored to specific tasks and ground conditions. The two primary designs are the backhoe and face shovel buckets. Backhoe buckets, with their curved bottoms and narrow tips, are ideal for trenching and digging in tight spaces. Face shovel buckets, on the other hand, have flatter bottoms and larger capacities, making them perfect for bulk material handling and excavation.

-

Reinforced for Toughness:

To withstand the relentless wear and tear in demanding environments, excavator bucket is reinforced with hardened steel components. These wear-resistant plates and cutting edges minimize abrasion and ensure optimal digging efficiency. Innovative designs also incorporate replaceable teeth and adapters, allowing quick and cost-effective maintenance.

-

Beyond the Basics: Specialized Attachments:

Excavator buckets are highly versatile and can be equipped with various specialized attachments to enhance their functionality. Some popular attachments include grapples for handling loose materials, rippers for breaking up hard surfaces, and thumbs for gripping irregularly shaped objects. This flexibility makes excavator buckets invaluable in a wide range of construction, mining, and demolition applications.

-

Enhancing Efficiency with Technology:

Advancements in technology have transformed excavator bucket, maximizing their productivity and efficiency. Hydraulic systems now allow operators to control the bucket’s movements with precision, optimizing digging depth and speed. Additionally, sensors and cameras provide real-time data, enabling operators to monitor the bucket’s position, load, and ground conditions, ensuring safer and more efficient operations.

-

Adaptability for Different Environments:

Excavator buckets are designed to conquer diverse terrains and ground conditions. Specialized buckets are available for specific environments, such as rock buckets for rocky landscapes or ditching buckets for shaping ditches and trenches. Some buckets even feature advanced tilting mechanisms, allowing operators to work on uneven surfaces without compromising efficiency.

-

Sustainable Solutions:

In recent years, environmental considerations have driven the development of sustainable excavator bucket solutions. Lighter yet durable materials are being used to reduce fuel consumption and carbon emissions. Additionally, advanced hydraulic systems minimize energy consumption, and the adoption of renewable power sources, such as electric excavators, further contributes to a greener future.

-

The Future of Excavator Buckets:

The evolution of excavator bucket continues as technology advances. Automation and autonomous systems are gradually being integrated, enhancing safety and efficiency on job sites. Furthermore, materials science and engineering breakthroughs may lead to the development of even stronger and lighter bucket materials, improving performance while reducing environmental impact.

Conclusion:

Excavator buckets stand as testament to human ingenuity and innovation, revolutionizing the way we shape the world around us. From their meticulous production process to their versatile design features and innovative technologies, these workhorses enable us to accomplish feats that were once unimaginable. As we continue to push the boundaries

of construction and excavation, the future of excavator buckets holds exciting possibilities. With ongoing advancements in materials, technology, and sustainability, we can anticipate even more efficient, durable, and environmentally friendly solutions.

As we look ahead, automation and autonomous systems are expected to play a significant role in the evolution of excavator bucket. These intelligent machines will be capable of executing repetitive tasks with high precision, minimizing human error and improving overall productivity. With the integration of advanced sensors, machine learning algorithms, and real-time data analysis, excavator buckets will become even more efficient, adaptive, and safer to operate.

Moreover, materials science and engineering research may lead to the development of new materials with superior strength-to-weight ratios. Lightweight yet robust materials will contribute to reducing fuel consumption and carbon emissions, while also allowing excavator buckets to handle heavier loads and operate with increased agility. Additionally, the utilization of advanced composites and coatings may enhance wear resistance, further extending the lifespan of excavator buckets and reducing maintenance requirements.

The quest for sustainability in the construction industry has given rise to eco-friendly initiatives, and excavator buckets are no exception. Manufacturers are actively exploring ways to reduce the environmental impact of these machines. This includes incorporating more recycled materials into the production process, optimizing energy efficiency through hydraulic system improvements, and embracing alternative power sources such as electric excavators. By prioritizing sustainability, excavator buckets can contribute to a greener future by minimizing resource consumption and carbon emissions.

In conclusion, excavator buckets are indispensable tools that have revolutionized the construction and mining industries. From their meticulous production process to their diverse design features and the integration of advanced technologies, they continue to push the boundaries of what is possible. With ongoing advancements in automation, materials science, and sustainability, the future of excavator buckets holds immense potential for increased efficiency, durability, and environmental consciousness. As these machines evolve, they will undoubtedly play a vital role in shaping a sustainable and technologically advanced future.

Leave A Comment