When we see an excavator in action, we often marvel at the immense power and efficiency of these heavy machines. However, what often goes unnoticed is the incredible science and engineering that goes into the creation of their essential component – the excavator bucket. The bucket is the workhorse of the excavator, responsible for digging, lifting, and carrying heavy loads of earth and materials. Crafting a high-performance excavator bucket requires careful planning, materials selection, and precision engineering. In this article, we will delve into the fascinating world of excavator buckets and explore the work and preparations that are necessary before they are put to work.

-

Understanding the Job

Before crafting an excavator bucket, it’s essential to understand the specific tasks it will be used for. Excavators are versatile machines used in various applications, such as construction, mining, and agriculture. The type of bucket required for each task can vary significantly. For example, a digging bucket used in construction may have a different design and materials than a rock bucket used in mining.

-

Material Selection for Excavator Bucket

The choice of materials for an excavator bucket is critical to its performance and durability. Most excavator buckets are made from high-strength steel, but the exact alloy and thickness can vary. The material must be strong enough to withstand the forces exerted during digging and lifting while still being resistant to wear and abrasion. To select the right material, engineers consider factors such as the type of soil or material being excavated, the operating conditions (temperature, moisture, etc.), and the expected lifetime of the bucket.

-

Excavator Bucket Design

Bucket design is a complex process that involves optimizing the shape, size, and internal structure of the bucket. Engineers use computer-aided design (CAD) software to create 3D models of the bucket and simulate its performance under various conditions. This allows them to refine the design for efficiency and structural integrity.

The bucket’s cutting edge, teeth, and shape are carefully engineered to maximize digging and loading capabilities. Teeth on the bucket’s leading edge are strategically placed to break through tough soil or rocks efficiently. The shape of the bucket is designed to scoop and retain materials effectively.

-

Structural Integrity

Ensuring the structural integrity of the excavator bucket is vital for its longevity and safety. Engineers conduct stress analysis to identify potential weak points in the bucket’s design and make necessary adjustments. Finite element analysis (FEA) is often employed to simulate how the bucket will behave under various loads and conditions.

Buckets may be subject to fatigue, bending, and torsional forces during operation. By analyzing these forces, engineers can make changes to the bucket’s design to reinforce weak areas and reduce the risk of structural failure.

-

Heat Treatment

After the initial bucket design is complete, the steel material undergoes heat treatment. This process involves heating the steel to a specific temperature and then rapidly cooling it. Heat treatment improves the steel’s hardness, strength, and durability. It also helps minimize internal stresses within the material, enhancing its resistance to cracking or deformation.

-

Excavator Bucket Welding and Assembly

The assembly of an excavator bucket involves precision welding to ensure that all components are securely attached. Skilled welders meticulously join the various parts of the bucket, including the cutting edge, teeth, and sidewalls. The quality of the welding process is crucial to the bucket’s performance and longevity, as weak welds can lead to structural failures.

-

Hardfacing

In many cases, the cutting edge and teeth of the excavator bucket undergo hardfacing. Hardfacing is the application of a wear-resistant layer of metal to specific areas of the bucket that are prone to abrasion. This extra layer protects the bucket from premature wear and tear, extending its service life.

-

Quality Control

Quality control is a critical step in the preparation of an excavator bucket. To ensure that each bucket meets the highest standards, a series of inspections and tests are carried out. This includes non-destructive testing, visual inspections, and dimensional checks to verify that the bucket’s dimensions and welds are in compliance with design specifications.

-

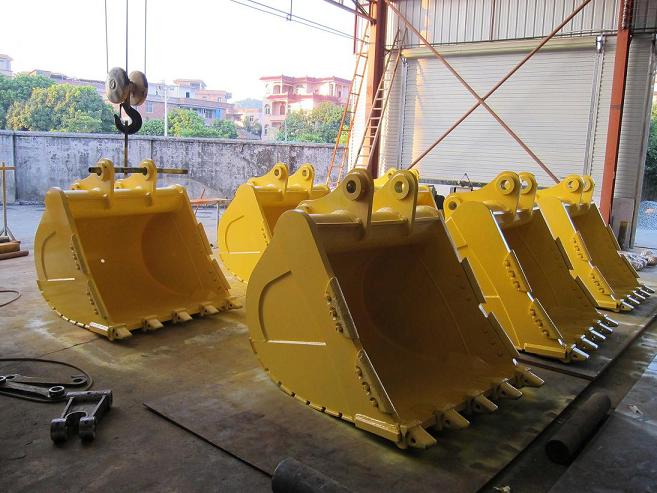

Surface Coating

To protect the excavator bucket from corrosion and maintain its appearance, a surface coating may be applied. Common coatings include paint or powder coating, both of which provide a layer of protection against environmental factors.

-

Excavator Bucket Performance Testing

Before the excavator bucket is ready for use, it undergoes rigorous performance testing. This involves attaching it to an excavator and subjecting it to real-world conditions. Engineers evaluate its digging and lifting capabilities, checking for any signs of weakness or wear. This testing ensures that the bucket is fit for its intended purpose.

Conclusion

Crafting an excavator bucket is a complex and highly specialized process that combines science, engineering, and craftsmanship. The careful selection of materials, precise design, structural integrity, and quality control measures are all essential to ensure that the excavator bucket performs reliably and efficiently over its lifespan. The next time you see an excavator at work, remember the science and engineering that went into creating its indispensable tool—the excavator bucket. It’s a testament to human innovation and ingenuity, turning raw materials into a mighty force of construction and excavation.

Leave A Comment