As an important construction machinery and equipment, the excavator plays an indispensable role in modern construction, mining and infrastructure projects. Its working device is composed of multiple complex components, among which the excavator H-link is the key component connecting the digging arm and the bucket (bucket). This article will analyze the characteristics and functions of the H-link in detail, and introduce the importance of its daily maintenance to help you better understand the working principle and maintenance methods of this important part.

What is the H-link?

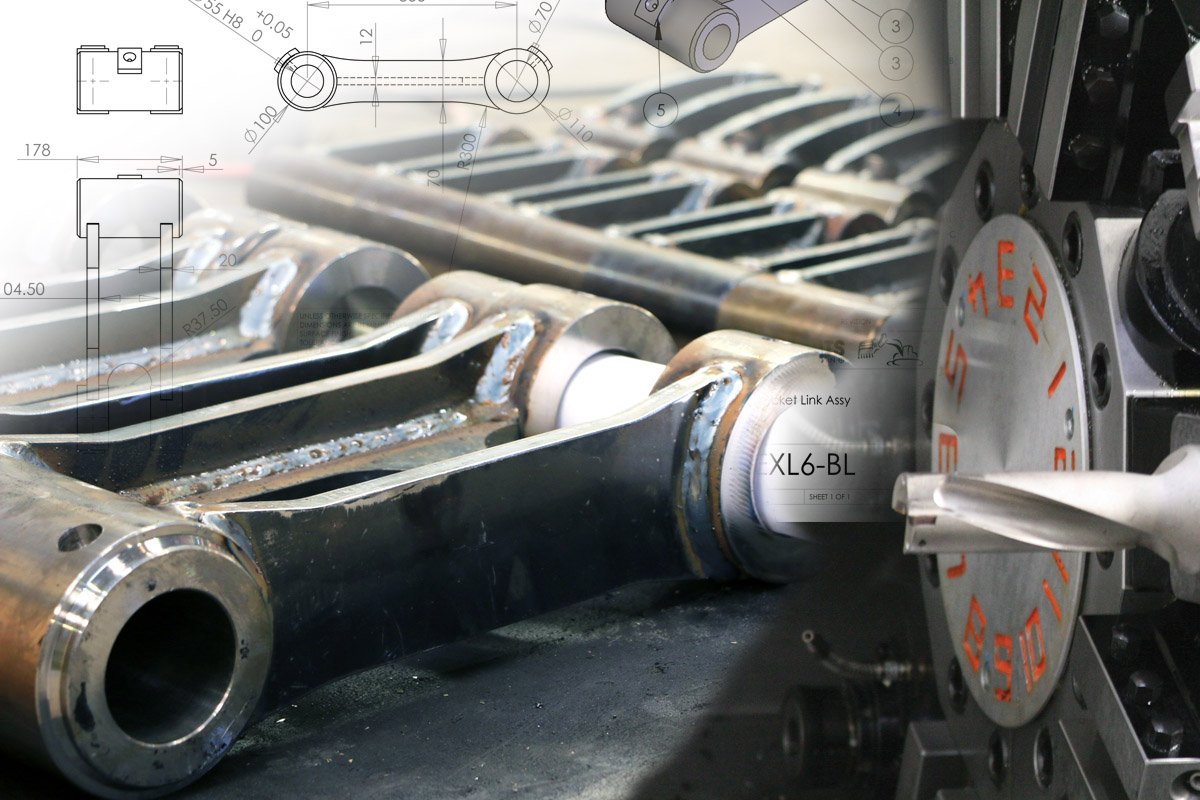

The excavator H-link, also known as the H-type link, as the name suggests, is shaped like the letter “H”. It is a structural part used to connect the digging arm and the bucket in the excavator working device. The H-link plays a vital role in the working process of the excavator. It is not only responsible for connecting the working arm and the bucket, but also bears the heavy responsibility of bearing and transmitting force during work.

The hydraulic system of the excavator generates thrust through the hydraulic cylinder, so that the H-link drives the bucket to perform complex movements such as up and down, forward and backward at the connection part. The H-link of different brands and models of excavators may have different structures, but they all have similar functions: working together to enable the bucket to complete earthwork excavation, bulldozing, shoveling and other operations at different angles, depths and positions.

Main features of the excavator H-link

-

Structural design:

The appearance of the H-link is shown in the letter “H”. This design gives the link good strength and stability. The excavator H-linkis often made of high-strength steel, which can withstand huge workloads and ensure long-term stability. It is usually located at the end of the digging arm and is connected to the bucket by a hinge pin, so that the hydraulic thrust of the digging arm can be transmitted.

-

Connection and transmission function:

An important function of the H-frameis to connect the working arm and the bucket. Its work enables the excavator to flexibly adjust the bucket angle and depth. Through the work of the hydraulic cylinder, the H-link will drive the bucket to complete a certain motion trajectory and perform tasks such as shoveling, bulldozing, and handling.

-

Durability and load bearing:

During the operation of the excavator, the H-framewill be subjected to a lot of impact and reaction force, especially when excavating hard soil or rock, the pressure and friction of the H-link are huge. Therefore, its materials and manufacturing processes are required to have high strength and durability, usually using high-strength steel or other wear-resistant materials.

-

Strong adaptability:

The excavator H-linkcan adapt to excavation operations under different working conditions, whether it is deep excavation, hard soil or loose soil, it can ensure the stability and efficiency of the bucket. Due to its unique connection method, the H-frame has good adaptability to different types of excavation operation scenarios.

Daily maintenance of excavator H-link

Although the design of the H-link is very strong, it still faces wear, corrosion and other damage in daily use. Regular maintenance can significantly extend the service life of the H-link and the entire machine and improve the working efficiency of the excavator. The following are some suggestions for daily maintenance:

-

Check the connection parts:

Regularly check the connection parts between the H-link and the excavation arm and bucket to ensure that the connecting pins are not loose, worn or deformed. If the connection is found to be loose or cracked, the pin should be adjusted or replaced in time to avoid unstable operation or damage due to loose parts.

-

Lubrication and maintenance:

Lubrication is an important means to reduce friction and wear at the joints of the H-link. Regularly lubricate the movable joints of the H-link to ensure the normal operation of the hydraulic system and prevent friction loss caused by insufficient lubrication. Especially in high temperature and high load working environments, good lubrication can effectively reduce wear and extend the service life of the connecting rod.

-

Check structural integrity:

Regularly check whether the excavator H-linkbody has cracks, deformation or corrosion. Especially after heavy load operations, check whether the connecting rod is overly fatigued to avoid more serious mechanical failures caused by connecting rod damage. If necessary, stress analysis can be performed on it through professional testing equipment to ensure the safety of the structure.

-

Cleaning and rust prevention:

When the excavator is working in the open air, the H-link is easily contaminated by mud, dust and moisture, and long-term accumulation may cause corrosion problems. Regularly clean the dirt on the surface of the H-link and perform rust prevention treatment to effectively prevent corrosion and oxidation and ensure the long-term durability of parts.

-

Hydraulic system inspection:

The action of the excavator H-linkdepends on the normal operation of the hydraulic system, so checking whether the oil in the hydraulic system is clean and whether the oil pressure is normal is also part of the maintenance. The quality of the oil directly affects the working efficiency and service life of the H-link.

-

Monitor the load:

Avoid the excavator H-linkfrom working under overload. Excessive load will not only cause fatigue of the H-link, but also increase the pressure of the entire excavator hydraulic system. By monitoring the workload, mechanical failures can be prevented and the efficient operation of the equipment can be ensured.

Summary

As a key component in the excavator working device, the excavator H-link not only connects the digging arm and the bucket, but also bears the task of carrying and transmitting force. Its design enables it to withstand heavy loads and adapt to various working environments, ensuring the efficient operation of the excavator under complex working conditions.

Correct daily maintenance can not only ensure the stable operation of the excavator H-link, but also extend the service life of the entire machine. In actual operation, regular inspection, lubrication, cleaning and monitoring of the hydraulic system are all essential maintenance measures. Through these meticulous maintenance, you can maximize the efficiency of the excavator and avoid economic losses caused by damaged parts.

If you want to know more about excavator maintenance knowledge or the working principles of other mechanical parts, please continue to pay attention to our website!

Leave A Comment