Revolutionize Your Excavation: Say goodbye to limitations and hello to unprecedented efficiency with our Excavator Long Reach Boom. Engineered with precision and crafted from high-quality materials, this boom is designed to enhance your excavator’s performance, enabling you to take on complex projects with ease and precision.

Long Reach Boom and Arm

Description

Excavator Long Reach Boom is one of best selling products. HITE has a long history of supplying long reach fronts packages for excavator weights from 8T- 180T. With our expertise in designing and manufacturing Long Reach Booms, you can achive max.ROI on your existing fleet of excavators.

Equipped with a longer arm and a specialized boom configuration, our excavator long reach boom allows you to access hard-to-reach areas and work efficiently in deep excavations. Whether you’re involved in dredging, riverbank maintenance, or demolition projects, this product will significantly increase your productivity and efficiency. Its exceptional durability ensures reliable performance, even in the toughest operating conditions.

We design the long reach front with structural grade tensile steel. Welding is done by experienced welder with over 8 years of experience, at least. The whole production process incompliance with ISO 9001 standard, and they are all CE certificated.

Safety is our top priority, and we have incorporated several innovative features into the design of our long reach boom. With advanced stability systems and reinforced structure, you can trust that your operators will have a secure working environment. Additionally, the boom is equipped with state-of-the-art hydraulic controls, providing smooth and precise movements for precise digging and lifting operations.

Investing in our excavator long reach boom means investing in improved productivity, safety, and versatility for your construction projects. Join the ranks of satisfied customers who have experienced the outstanding performance and reliability of our product. Contact us today to learn more about how our long reach boom can revolutionize your excavating operations and take your business to new heights.

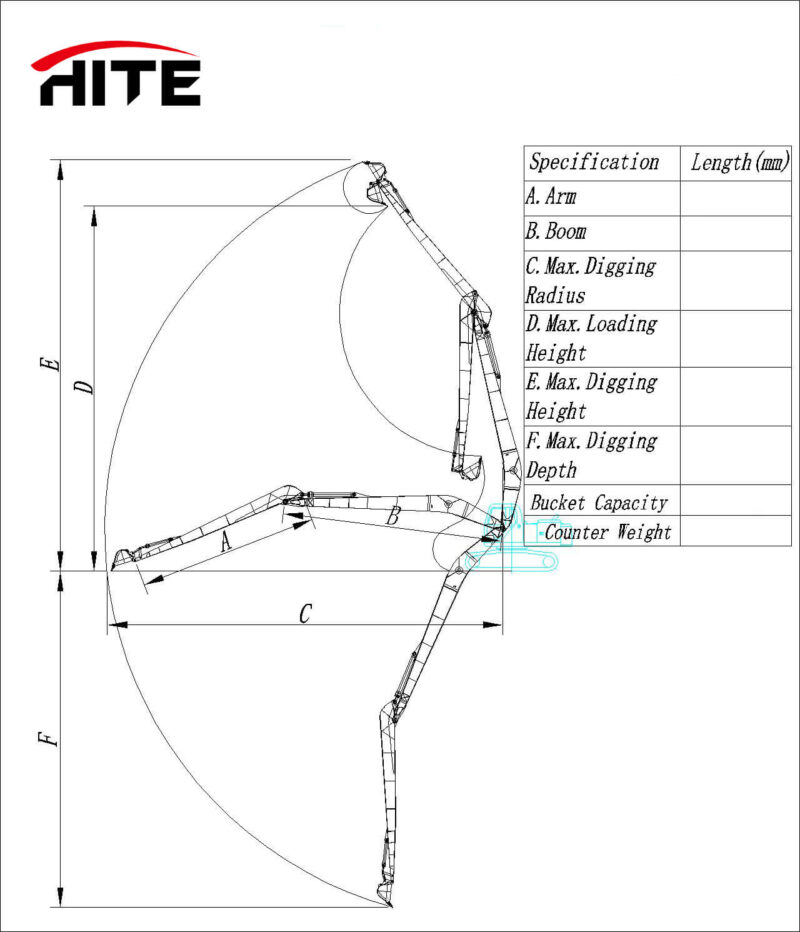

Excavator Long Reach Boom Construction Scope Map

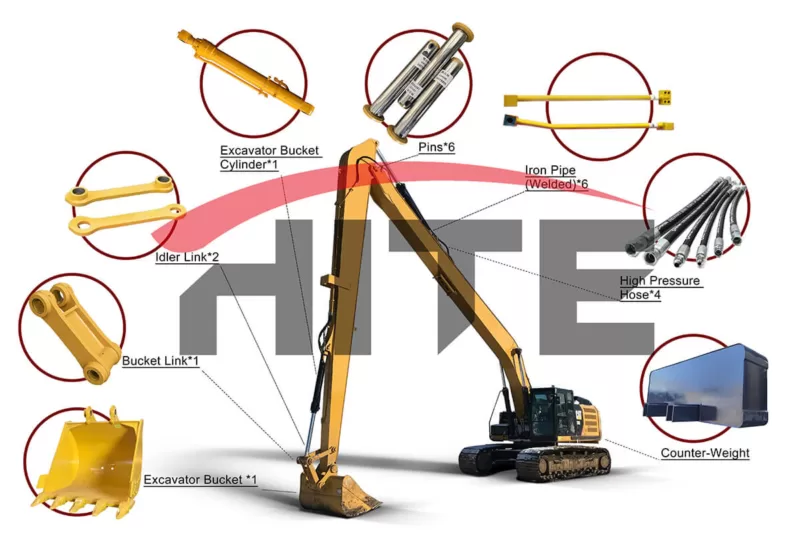

Long Reach Boom Configuration Diagram

3D Modeling Diagram For Excavator Long Front Boom

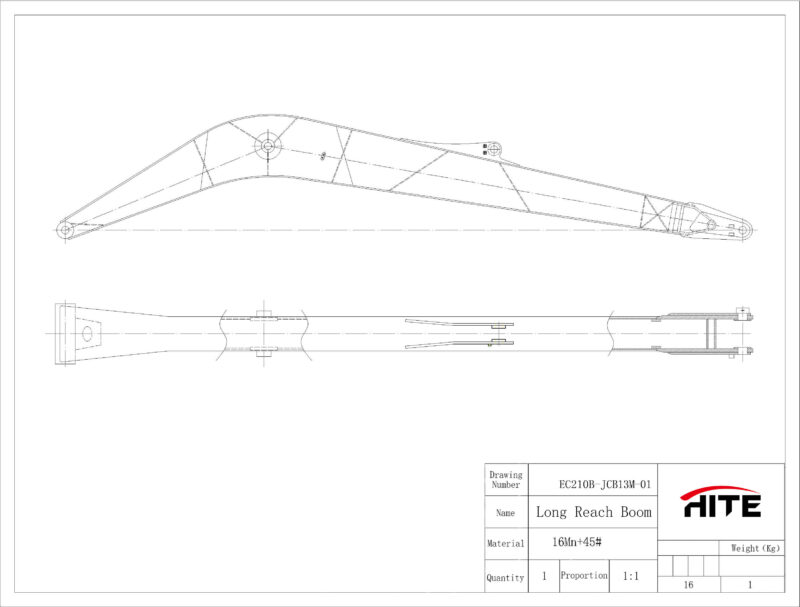

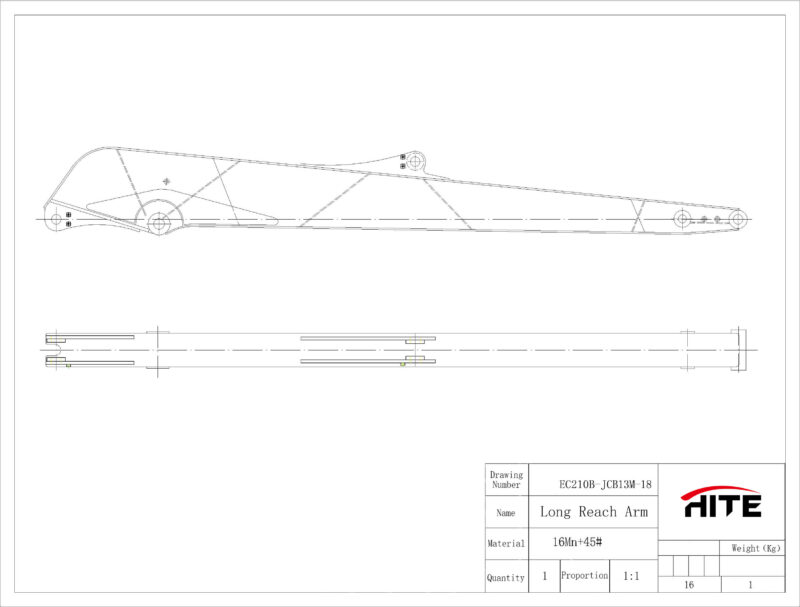

Excavator Long Reach Boom General Arrangement Drawing

| Machine Tonnage | Extension boom | Extended arm | Height while transport | Digging radius | Max.unloading height | Max.Digging height | Max.Digging depth | Bucket capacity(m³) | Cylinder(T) | Weight while working(kg) |

| 12T | 7100mm | 5900mm | 2900mm | 11200mm | 7350mm | 9350mm | 9000mm | 0.3 | 12 | 3000 |

| 20T | 8220mm | 7160mm | 2980mm | 14500mm | 10390mm | 12510mm | 11340mm | 0.4 | 12 | 4000 |

| 35T | 8220mm | 7160mm | 3050mm | 14500mm | 10490mm | 12610mm | 11370mm | 0.4 | 12 | 4200 |

| 30T | 10000mm | 8000mm | 3210mm | 17300mm | 11720mm | 13920mm | 13010mm | 0.4 | 12 | 5200 |

| 35T | 11000mm | 9000mm | 3210mm | 19200mm | 12920mm | 15120mm | 15000mm | 0.5 | 12 | 6000 |

| 40T | 12000mm | 10000mm | 3400mm | 21100mm | 14240mm | 16980mm | 16500mm | 0.6 | 20 | 6500 |

| 45T | 13000mm | 11000mm | 3400mm | 22900mm | 15230mm | 17800mm | 18000mm | 0.6 | 20 | 7000 |

High-quality materials

| Material | Code | Related Chemical Composition | Hardness(HB) | Extension(%) | Drag and extension intensity (N/mm2) | Bend Intensity (N/mm2) | ||||

| C | Si | Mn | P | S | ||||||

| Alloy | Q355B | 0.18 | 0.55 | 1.4 | 0.03 | 0.03 | 163-187 | 21 | 470-660 | 355 |

| Chinese High-Strength alloy | NM360 | 0.2 | 0.3 | 1.3 | 0.02 | 0.006 | 360 | 16 | 1200 | 1020 |

| High-Strength alloy | HARDOX-500 | 0.2 | 0.7 | 1.7 | 0.025 | 0.01 | 470-500 | 8 | 1550 | 1300 |

Our Excavator Long Reach Booms Sticks fit most makes and models, Include but not limit below models.

- Komatsu Excavator Model: PC160LC-8, PC200, PC210, PC228, PC220 PC270, PC300, PC350, PC450, PC600, PC850, PC1250

- Caterpillar Excavator Model: CAT320, CAT323, CAT326, CAT329, CAT330, CAT335, CAT336, CAT349, CAT352, CAT374, CAT390

- Hitachi Excavator Model: ZX210, EX200, EX220, EX330, EX350, ZX200, ZX240, ZX330, EX350, EX400, ZX470, ZX670, ZX870, EX1200, EX1900

- Volvo Excavator Model: EC220, EC235, EC250, EC300, EC350, EC355, EC380, EC480, EC750

- Doosan Excavator Model: DX225, DX235, DX255, DX300, DX350, DX420, DX490, DX530, DX800

- Kobelco Excavator Model: SK200, SK210, SK220, SK250, SK260, SK300, SK330, SK350, SK380, SK460, SK500, SK850

- Sumitomo Excavator Model: SH210, SH225, SH240, SH300, SH330, SH350, SH460, SH480, SH500, SH700, SH800

- Hyundai Excavator Model: R200, R210, R220, R290, HX220, HX235, HX260, HX300, HX330, HX380, HX430, HX480, HX520, R1200

- KATO: HD250, HD400, HD450, HD550, HD700, HD800, HD820, HD900,HD1250,HD1430

- CASE: CX130B, CX210B, CX240B, CX360B, CX470B,CX800B

- LIEBHERR: R900C,R906, R916, R924, R926, R954, R964C, R974C, R984C

- JCB: JS130LC, JS220LC, JS240LC, JS290LC, JS360

- SANY: SY200C, SY210C, SY225, SY310C, SY420

- SUNWARD: SWE130, SWE150, SWE200, SWE210, SWE230, SWE470

TAG: excavator long front boom, excavator long reach front

Feature

1) Structure design based on FEA, more durable and efficient, saving your time in the shop.

2) All steel came from CSG, the top 50 steelmakers in China, Making sure the quality of our main raw material.

3) Phosphating tubes are used instead of a normal tube, providing excellent anti-corrosion and anti-rust ability to better protect the hydraulic system, and provide more power to the work.

4) Cooper sets have been used on the connector instead of normal steel sets used on the market.